Smart Grader EVO for tuberous crops

More accurate than the human eye

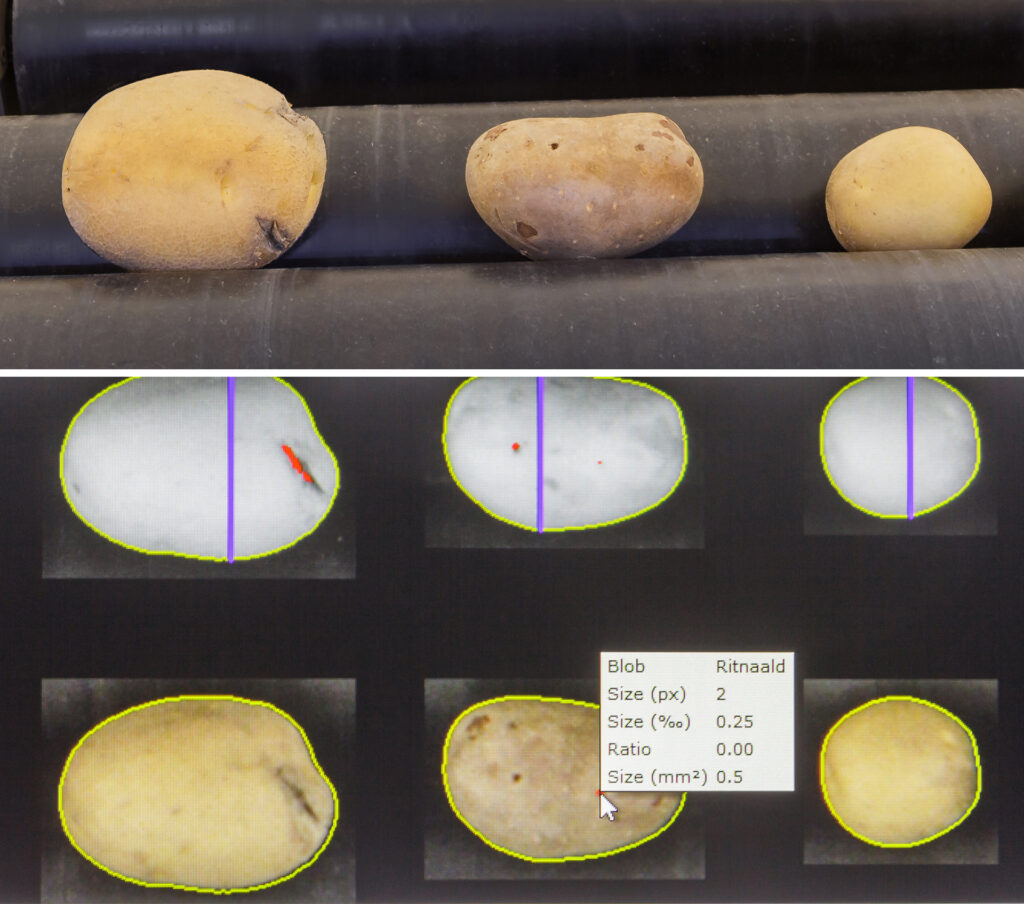

Most Smart Graders are mainly used for grading potatoes, but the grader is also ideal for shallots and onions. The supplied product flow is singulated on a vibrating table, so that the products can be guided individually one after the other over roller conveyors. This rolling movement makes it possible for the products to be viewed on all sides by high-resolution cameras. The images are quickly assessed by Ellips TrueSortTM software based on easy-to-set criteria. Even wireworms, scabies and bump marks are recognized flawlessly. Depending on the shape or quality characteristics, the products are blown off the belt at the correct exit; very effective and product friendly.

Unlimited capacity

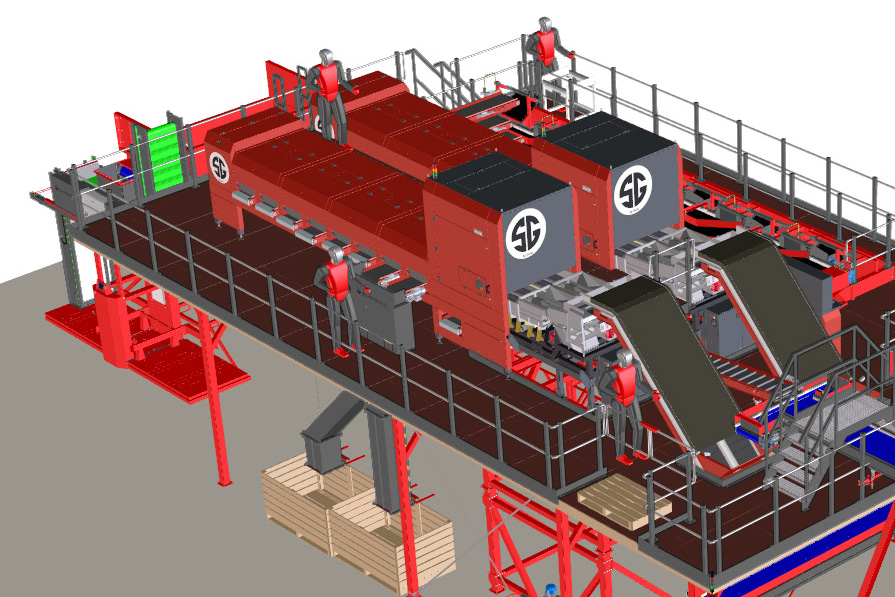

Smart Graders are available in versions with two, four, eight or twelve roller conveyors. By placing multiple Smart Graders next to each other, the sorting capacity is almost unlimited. We are happy to advise you in making the right choice, suitable for your company and application.

EVO = Evolution

With the Smart Grader EVO, EVO stands for Evolution. It is a further development of the first series of optical sorters and the result of our continuous search for innovation. The Smart Grader EVO sorts more accurately than humans will ever be able to, is tireless and works 24/7 with the same precision.

GeJo delivers total solutions!

GeJo Grading develops sorting solutions and these are always tailor-made. Most sorting installations are designed in close consultation with the customer and tailored to his circumstances. If desired, we also involve our partners such as Bijlsma Hercules and VHM. Because although our Smart Grader is the brain of the sorting process, the entire logistics surrounding it is of great importance for the sorting capacity and quality. All box layers, storage bunkers, cleaning units, supply and discharge conveyors, box fillers, etc. are all crucial for a perfect workflow. By coordinating all components of the sorting installation, optimal capacity can be achieved.

The Smart Grader is conquering the world

GeJo Grading has now supplied Smart Graders worldwide to satisfied customers who use optical grading. Smart Graders have been running satisfactorily for more than 15 years and every day we work on new installations that can work completely autonomously. Would you like to experience the results yourself? Please contact us and we will be happy to put you in touch with a Smart Grader user in your area.

User experiences

In recent years we have supplied many Smart Graders to satisfied customers. Below we would like to let them tell you about their experiences.